SMC Hot Pressed GRP/FRP Sectional Water Tank

What is SMC?

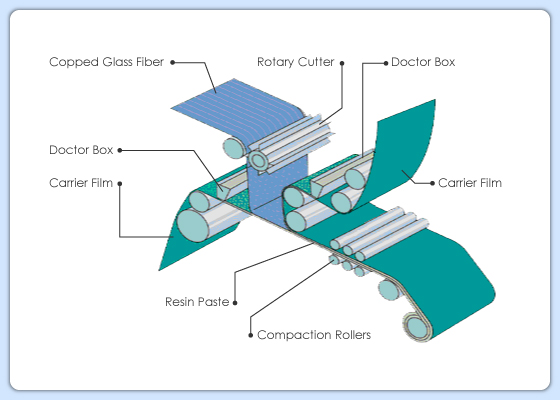

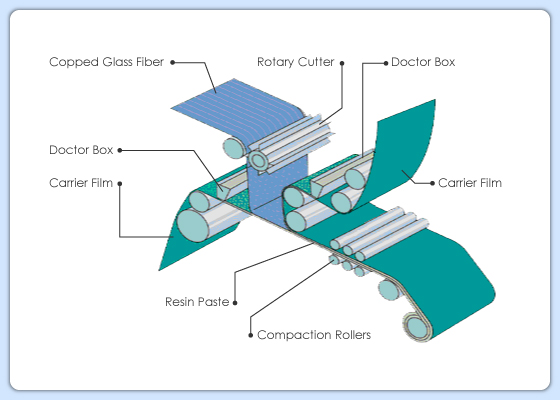

Sheet Moulding Compound (SMC) is sheet material for hot press mould. The SMC process is the most important process technology for fiber reinforced polymers today. SMC is a mixture of polymer resin, fillers, fiber reinforcement, catalysts, pigment and stabilizers, release agents, and thickeners. Manufacture of SMC is a continuous in-line process. The material is sheathed both top and bottom with a polyethylene or nylon plastic film to prevent auto-adhesion. The resin paste is spread uniformly onto the bottom film. Chopped glass fibers are randomly deposited onto the paste. The top film is introduced and the sandwich is rolled into a pre-determined thickness. The sheet is allowed to mature for 48 hours before shipment.

Heat represents one of the most difficult environments for a polymer. The cross-link reaction of covalent bonds that takes place when polyester thermoset is molded gives SMC compounds a distinct structural advantage over alternative materials, such as thermoplastic, at elevated temperatures. Relaxation or creep failure is far less in a chemically reacted thermoset composit than a “cooled to form” (cold pressed/hand lay-up) thermoplastic materials.

What is SMC?

Sheet Moulding Compound (SMC) is sheet material for hot press mould. The SMC process is the most important process technology for fiber reinforced polymers today. SMC is a mixture of polymer resin, fillers, fiber reinforcement, catalysts, pigment and stabilizers, release agents, and thickeners. Manufacture of SMC is a continuous in-line process. The material is sheathed both top and bottom with a polyethylene or nylon plastic film to prevent auto-adhesion. The resin paste is spread uniformly onto the bottom film. Chopped glass fibers are randomly deposited onto the paste. The top film is introduced and the sandwich is rolled into a pre-determined thickness. The sheet is allowed to mature for 48 hours before shipment.

Heat represents one of the most difficult environments for a polymer. The cross-link reaction of covalent bonds that takes place when polyester thermoset is molded gives SMC compounds a distinct structural advantage over alternative materials, such as thermoplastic, at elevated temperatures. Relaxation or creep failure is far less in a chemically reacted thermoset composit than a “cooled to form” (cold pressed/hand lay-up) thermoplastic materials.